Natural gas pipeline for Volkswagen with an inbuilt future

In Wolfsburg, two state-of-the-art gas-fired power plants will secure the future energy supply for the Volkswagen plant and the City of Wolfsburg. To ensure they can also be operated with hydrogen in the longer term, Mannesmann H2ready® pipes have been used in the construction of the supply line.

"For us, and certainly also for the network operator Gasunie and the VW Group, this is a milestone on the road to the future."Manuel Simm, Regional Sales Manager Mannesmann Line Pipe

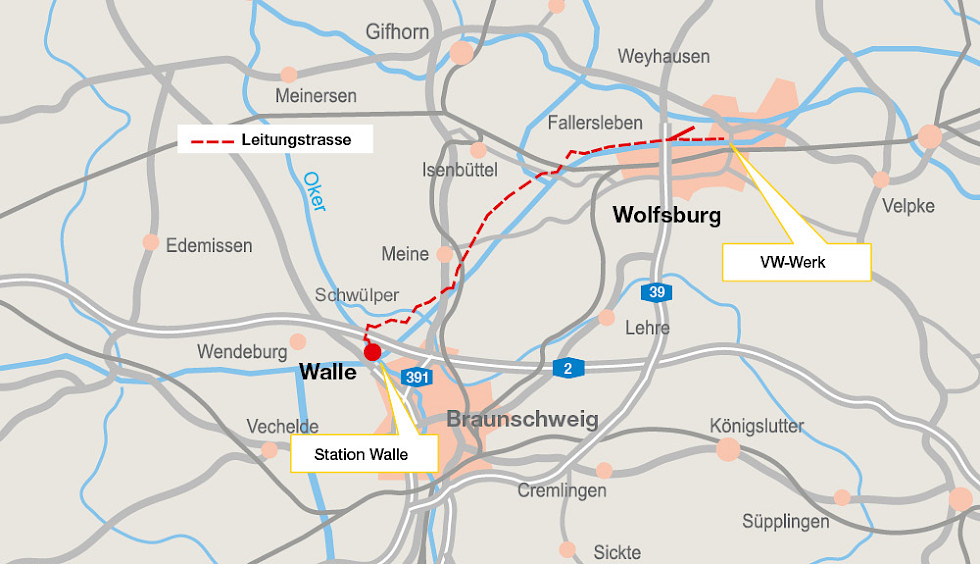

The highly advanced combined-cycle gas turbine power plants will replace the previously coal-fired north/south power plant units and the west power plant. To switch the energy supply of the VW plant and the City of Wolfsburg to natural gas, a 33 km high-pressure gas pipeline has been laid from the Walle connection station north of Braunschweig to the VW plant site in Wolfsburg. The client is Gasunie, the Dutch gas network operator. Gasunie has a roughly 16,000-kilometer natural gas transmission network in the Netherlands and northern Germany. In Germany alone, it has some 4,300 kilometers of high-pressure pipelines. Around EUR 80 million is being invested in the new pipeline, says Gasunie.

HFI-welded steel pipes in the new gray-and-red design

In a forward-looking approach, the pipeline has been designed and built for the operation and transport of hydrogen. Helping to make this possible are the new Mannesmann H2ready® pipes. What is new here is not only their technical configuration, which in some cases even exceeds the requirements of the EIGA guideline for the transport of hydrogen, but also their appearance. As there is no binding color coding yet for hydrogen, it was agreed with Gasunie to coat the pipes with PE in light gray with red stripes. Manuel Simm, who oversaw the project on behalf of Mannesmann Line Pipe, was also responsible for consultations on the technical specifications and production of the HFI-welded steel pipes: "In total, we’re talking about almost 1,900 pipes with single lengths of up to 18 meters." The grade has the designation L360NE, and the pipe diameter is 400 mm. "To withstand the planned operating pressure of 84 bar, the pipes mainly have a wall thickness of 10 mm," Simm continues. "To ensure that at first natural gas and later hydrogen can flow efficiently through the pipeline, the pipes are lined with epoxy resin flowcoat."

Minimal impact on the natural environment

The planners paid particular attention not only to the specification of the new supply line, but also to minimizing the impact on the environment during installation. The route thus runs parallel to an existing pipeline and underwent trenchless laying over a length of 9 km with minimal impact on the natural environment. "For this purpose, the pipes were given a reinforced PE coating and an additional one of glass-reinforced plastic to optimally protect the pipe string from mechanical damage in the ground," Simm explains.

A total of 14 HDD (Horizontal Directional Drilling) boreholes were drilled under rivers, canals, roads and railroad tracks. Such a special technical and logistical challenge arose towards the end of the demanding pipeline project in November 2021, when the pipeline had to underpass the 'Südliche Düpenwiesen' nature reserve to the west of the VW plant site and the A39 freeway. After around nine and a half hours of work, the 1.9 km long pipe string arrived at its destination well ahead of schedule. On February 9, 2022, Gasunie then announced the completion of the new Walle-Wolfsburg high-pressure gas pipeline.

Laying the foundations for secure supplies

With the completion of the pipeline and the construction or extension of a total of six gate valve stations along the route, the foundations have been laid for the connection and operation of the new combined-cycle gas turbine power plants in Wolfsburg. The changeover from coal to natural gas is to be accomplished by November 2022 so that a secure energy supply can continue to be safeguarded to the VW plant in Wolfsburg. Beyond the plant boundaries, the VW Kraftwerk GmbH power generating company also supplies the municipality of Wolfsburg with electricity and district heat.

The pipeline route runs from the Walle station to the VW plant in Wolfsburg 33 km away.

Massive carbon savings

For VW, the power plant changeover is key to its 'goTOzero' strategy to improve its environmental footprint. According to Volkswagen Kraftwerk GmbH, running the new power plants at the Wolfsburg production site on natural gas will from now on save around 1.5 million metric tons of carbon compared with current emissions. A cut of around 60% or, to put it in automotive terms, a reduction equivalent to the average annual carbon emissions of 870,000 autos.

Showcase project of a special kind

"For us, and certainly also for the network operator Gasunie and the VW Group, this is a milestone on the road to the future," says Simm. "We have every reason to be proud of being able to help to decarbonize vehicle production in Germany with our German-made premium pipes," says the 35-year-old Regional Sales Manager. That green hydrogen will then be able to flow through the pipe in the near future puts the icing on the cake, in his view. "An absolute showcase project: a high-pressure natural gas pipeline with an inbuilt future."

The Wolfsburg Volkswagen site – the world’s biggest production plant

The Volkswagen plant in Wolfsburg is the parent plant of Volkswagen AG. In the late 1930s, it was built at the same time as a totally new city. The 'City of the "Strength through Joy" Car (or Beetle) near Fallersleben' was then renamed Wolfsburg in 1945. Occupying a total area of 6.5 million m², the plant is the world’s largest factory. At the end of 2018, around 63,300 people were employed at the Wolfsburg site, producing over 700,000 vehicles per year.

The last of the over 11.9 million VW Beetles built at the parent plant rolled off the Wolfsburg assembly line on July 1, 1974. The Golf then successfully replaced it and is still produced in Wolfsburg today in numerous variants, also now including the e-Golf. Around 70% of the finished cars are transported by rail via the connecting line to Fallersleben station. The VW plant’s rail network comprises 60 km of track and 157 switches and ranks as Europe’s biggest private loading station.

Volkswagen 'New Auto'

With its group strategy 'New Auto – Mobility for Generations to Come,' Volkswagen AG, which comprises such brands as Audi, Porsche, Seat and Škoda, is responding to the massive shift in the world of mobility and to climate change.

Its guiding principle is the development of sustainable, connected, safe and tailored mobility solutions for future generations. VW wants to realign itself from vehicle manufacturer to a leading, global software-driven mobility provider. A company that is redefining mobilitywhile also doing business climate-neutrally and conscientiously.

'GoTOzero' strategy

VW intends to become a carbon-neutral company by 2050. By 2025, production-related environmental externalities (carbon, energy, water, waste, volatile organic compounds) are to be reduced by 45% per vehicle relative to 2010. By this time, the share of battery-electric vehicles in its model portfolio is to rise to between 20 and 25%. By 2030, the e-share of its new car fleet in Europe and China is to grow to at least 40%.

"The car and individual mobility have a bright future. With its innovative brands and state-of-the-art technology platforms, Volkswagen is preparing to play a leading role in the new mobility world."Herbert Dies, CEO Volkswagen AG