Sustainability

Reconciling economic, environmental and social requirements

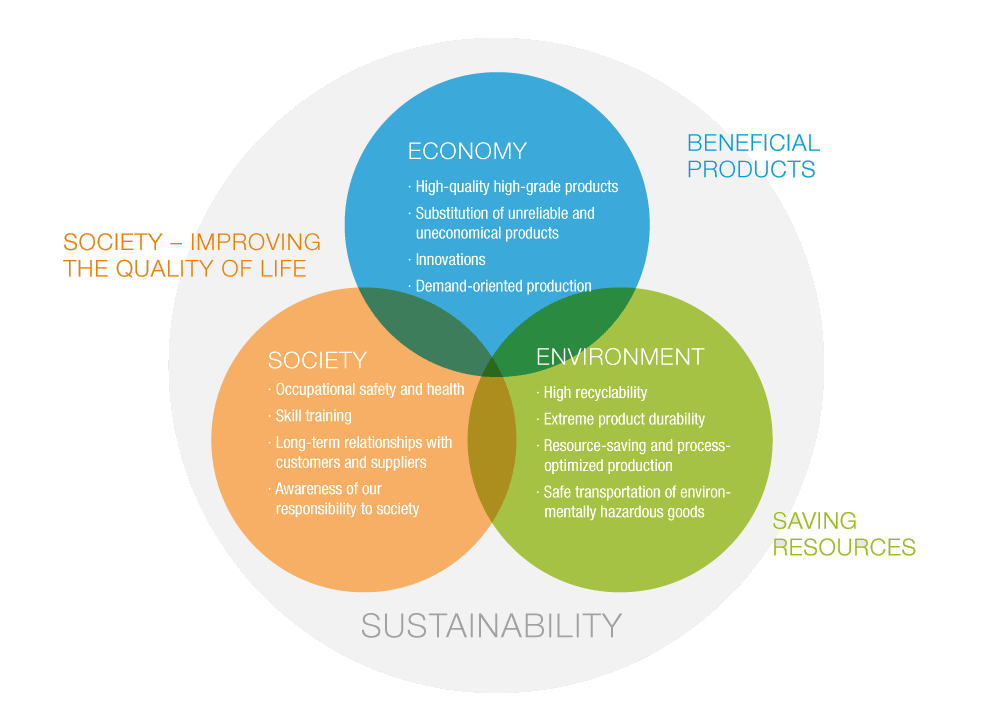

The term sustainability is used and interpreted differently in different contexts. Salzgitter Mannesmann Line Pipe has laid down long-term objectives regarding the impact of its activities on the environment, economy and society. In this way, a high degree of compatibility is created between the three areas.

One important goal is to generate value and avoid waste. Which is why sustainability is closely linked to “lean” activities at Salzgitter Mannesmann Line Pipe. "Avoiding waste" means avoiding overproduction, reactive power, quality problems and unnecessary information flows.

"Creating value" means that products and services from Salzgitter Mannesmann Line Pipe must work for their intended purpose to the full satisfaction of the customer.

The three aspects of sustainability for Salzgitter Mannesmann Line Pipe

Environment – conserving resources and ensuring safety

Steel and steel products are nearly 100 % recyclable. In addition, they have an extremely long product and service cycle. Hardly another material is as variable, versatile and durable as steel. Accordingly, despite its energy-intensive production, it achieves an excellent energy balance in service. The German steel industry in general, and Salzgitter Mannesmann Line Pipe in particular, have long made great efforts to reduce energy and water consumption in the production and processing of steel. The companies in our supply chain as well as Salzgitter Mannesmann Line Pipe itself, have an efficient environmental management system in place and have been certified to DIN EN ISO 14001. In addition, our certification to DIN EN ISO 50001 documents our compliance with exacting standards in the field of energy management.

Economy – creating beneficial products and services

Another aspect of sustainability concerns the goods and products we deliver. The name Mannesmann has been synonymous with maximum product quality and reliability in steel tube production for over 100 years. Our present research and development activities perpetuate a tradition of continuous product improvement. This makes our products safer and more economical in service, and opens up ever-new application possibilities, the focus always being on user benefits and compliance with continuously more challenging customer requirements.

Society – improving the quality of life

The third aspect of sustainability is people. This extends from employees via sup-pliers right down to society in general. The occupational safety and health of our employees are as important as is a company culture centered on mutual respect. Our courses in skill training are both a contribution to society and an import-ant element in keeping us fit for the future. All our business relationships are built to last; we advise, accompany and support our customers through all project phases – on-site around the globe.

Steel tubes and MSH sections facilitate the efficient use of renewables

HFI-welded steel tubes and MSH sections play an important part in the utilization of renewable energies. Products from Salzgitter Mannesmann Line Pipe can be found in nearly all such environments.

Wind power

Offshore wind farms offer a variety of applications for circular, square and rectangular MSH sections from Salzgitter Mannesmann Line Pipe. Besides jacket structures for the foundations of wind turbines and transformer platforms, HFI-welded steel tubes in grade S355 with diameters up to 610 mm and wall thicknesses up to 25.4 mm are used in peripheral applications such as cable conduits, boat landings and supply platforms.

Hydropower

HFI-welded steel pipe has long been used in various applications in hydro-electric power plants. Whether sweet or salt water, line pipe or high-pressure piping systems – Salzgitter Mannesmann Line Pipe offers its customers the perfect product for every application, complete with a comprehensive range of coatings and linings.

Geothermal energy

Technology for drilling deep geothermal exploratory and production wells can rely on the HFI-welded line pipe and oilfield tubulars (OCTG) which have already proved themselves for decades in the oil and gas industry. The on- going product improvements and innovations in these application areas are now feeding through to the geothermal industry. Similar to district heat systems, the operating temperature of hot pipes from geothermal wells very often goes well beyond 100 °C. This places high demands on the thermal expansion of the pipes.

Salzgitter Mannesmann Line Pipe can draw on decades of experience as a supplier to the leading system pipe manufacturers. We offer a full spectrum of products for the most varied applications, in a wide range of grades and with outside diameters up to 610 mm and wall thicknesses up to 25.4 mm.

Use of sustainable products in classic applications

Pipelines – maximum safety for our environment

Due to their exacting quality standard, products from Salzgitter Mannesmann Line Pipe are particularly reliable and provide for the safe and resource-saving transportation of hazardous substances, for example, in pipelines. Even though oil and gas pipelines do not transport renewable energy sources, they replace the need for thousands of haulages by road, rail or water.

Steel as a construction material – the epitome of sustainability

Steel tube structures can enclose more space than, for example, concrete ones, for the same amount of energy consumption. At the same time, steel is always an investment in a valuable raw material. Intelligently used, it is not only easy to assemble, but equally easy to recover when a structure is taken down, and it offers up to 100 % recyclability. In bridge construction projects, for example, the re-use of the recovered steel covers the cost of dismantling and demolition of the old bridge. And there‘s another advantage that steel brings with it: components for load-bearing structures can be manufactured with millimeter precision, or they can be preassembled to complete structures and delivered straight to the construction site just in time. This saves valuable storage space, facilitates logistics and shortens project times – a benefit over other construction methods that shouldn‘t be under-estimated.