Tradition and innovation

Much achieved but much more ahead

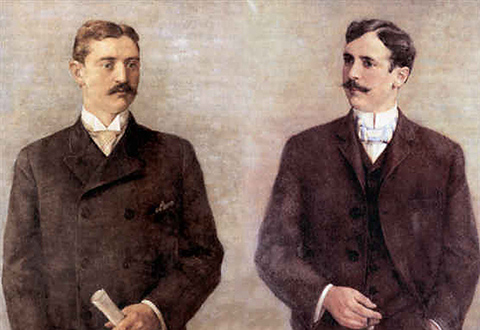

Mannesmann steel tubes, for which brothers Reinhard and Max Mannesmann filed a patent in 1885, soon became a global byword for ultimate quality and reliability. Today, they stand for 130 years' experience as a basis for shaping the world of tomorrow.

What started in 1890, when the first-ever high-pressure oil pipeline was laid through the Caucasus, has become the lifeline of our globalized economy: the worldwide efficient and safe distribution of energy carriers – mineral oil and natural gas – via a grid of steel pipelines several 100,000 km in length.

Steel tube and pipe and MSH sections from Salzgitter Mannesmann Line Pipe and Salzgitter Mannesmann Großrohr are also used in numerous other applications. From energy and water transportation to storage caverns and district heating systems for the reduction of CO² emissions right up to ultra-modern stadium and building construction projects, offshore wind parks and intelligent waste disposal strategies in metropolitan areas and conurbations.

Getting better and being better

Innovation is development and progress – getting better and being better. Making better products, implementing better processes, and providing better services.

Our continuous improvement in all these areas is based on our traditional strengths: research & development, production expertise, the training of skilled workers, quality, reliability, internationality, close intra-group ties, continuity and customer focus. All this combined helps us to develop innovative products, applications and services.

The company founders Reinhard and Max Mannesmann

We regard tradition not as backward-looking, but in fact as the foundation for our future.Heinrich Clören, Managing Director Sales & Marketing

Future users have been intensely involved right from the start in the development of the world's first app for mobile pipeline operations – PMT® lite.

The design, construction, operation and maintenance of pipelines generate a wealth of data. PMT® lite is the world's first app for an easy-to-use pipeline management system.

130 years of production expertise, continuous research and development, and the highest quality benchmarks ensure innovative products that meet the growing demands of our customers as well as setting new standards in application technology.

Traditional strengths – innovative products and applications

Consistent focusing on the needs and requirements of our customers plays a central role and will continue to do so. With PMT® Lite – the world's first app for mobile pipeline operations – we are opening up completely new possibilities for our customers. To ensure maximum added value and easy handling, we are involving future users in the development and implementation of ideas right from the start. This is just one example of many showing how we develop innovative products with a focus on customer needs.

Technical and social competencies

This development of new solutions tailored as closely as possible to customer needs is made possible by our broadly based production technology and – above all – by our employees. Sound training of skilled workers, dual study courses, occupational development and advancement measures, family friendly working hours and back-to-work programs are no passing fads for us but have long been firmly anchored in our corporate culture.

Besides purely technical aspects, social competencies have increasingly gained importance when it comes to recognizing customer needs and converting them into innovative solutions. Introductory, intermediate and advanced training courses enable our employees to emphasize our strengths such as continuity and customer focus.

Much achieved but much more ahead

We don't intend to rest on the laurels of 130 years' experience. Understanding our customers, recognizing their needs as well as relevant trends in good time is still as important as ever in the development of innovative products and applications. This is how we safeguard our competitive edge and sustainability.

Traditional strengths

Research & Development

The company founders Reinhard and Max Mannesmann patented over 1,000 technical ideas and improvements. And research and development still assume a central role in the implementation of innovative ideas.

Production expertise

130 years' experience in the manufacture and processing of steel tube and pipe. Expertise in which we are second to none.

Customer proximity

Our service is customer-oriented, readily accessible and committed. We advise, accompany and support our customers through all the phases of their projects.

Quality

The name Mannesmann stands for maximum product quality around the globe. This was true from the start and still is today.

Close intra-group ties

The Salzgitter Group is based on strong partners and close ties. We are optimally interlinked – from steel production and rolling competence right up to processing and fabrication.

Personnel training and development

The training of skilled workers as well as ongoing personnel development is an important factor in maintaining our competitive edge.

Continuity

We pursue our targets with perseverance. Strategies, partnerships and customer relations are built on a long-term basis.

Reliability

A promise is a promise. We guarantee agreed deadlines, qualities and delivery quantities.

Internationality

The very first high-pressure oil pipeline using Mannesmann line pipe was laid in the Caucasus back in 1890. Our business has always been and will continue to be international in every respect. Our employees altogether speak 13 languages either as their native tongue or as a second or third language.

Innovative products and applications

Line pipe

Our line pipe for the transportation of gases, combustible liquids and solids conforms to EN, API, ISO, GOST and DNV requirements. It is made to the most stringent specifications of renowned national and international oil and gas companies.

OCTG

Uniform pipe wall thicknesses and minimum out-of-roundness, coupled with outstanding collapse resistance. Conforming to API 5 CT and available in steel grades H 40, J 55, K 55, N 80 and HC 80.

Offshore wind energy turbines

High-grade hollow sections, cable conduits and corrosion protection for durable, economic wind park solutions.

Water pipe

A wide range of joints and connections, innovative coatings and linings for the most demanding applications in industrial plant and water pipelines.

Storage caverns

Underground storage and extraction of gas invariably involves extremely high pressures. Here, our pipes serve as safety-critical components under continuous dynamic stresses.

Structural tubes and MSH sections

Round, square and rectangular hollow sections for various types of buildings to facilitate optimal structures and encourage new architectural solutions.

Pipe for district heating systems

High-grade steel pipes (medium pipe and shells) for thermally insulated and electronically monitored pipe systems. Many years' experience with large projects and a wide range of pipe-laying and pulling processes.

Advice and services

Present around the globe

Our consultants and sales staff are at your side throughout all phases of your project. From the enquiry stage to the selection of the best-suited pipe-laying technique, technical specifications, processing and fabrication to logistics handling, complete with customs, carrier and shipping procedures, right up to the application of our products on the construction site.