Katharina underground gas storage project

New gas storage facility ensures ongoing supply security

About 88 % of the natural gas consumed in Germany is imported. To ensure reliable supplies, a large number of underground gas storage systems are operated across Germany. As of 2017, a new facility using steel pipes from Salzgitter Mannesmann Großrohr will provide additional supply security.

The classic task of underground gas storage systems is to compensate for seasonal and daily demand peaks. As with mineral oil, this buffer function is being increasingly backed up by strategic storage for times of crisis. Storage systems could, however, be employed for a further purpose in future, namely for the storage of synthetic natural gas obtained from excess wind and solar power.

Synthetic natural gas from electricity

While we are familiar with the use of natural gas to generate electricity, the reverse process may well be conceivable. For in 2010, German researchers succeeded in storing electricity as natural gas. The new process for the production of synthetic natural gas combines the technologies of hydrogen electrolysis and methanization for the first time. When hydrogen reacts with carbon dioxide, the result is methane, which is basically natural gas, albeit produced synthetically.

The ideal storage facility for excess wind and solar power

In their joint research, the scientists of the Centre for Solar Energy and Hydrogen Research Baden-Württemberg (ZSW) and the Fraunhofer Institute for Wind Energy and Energy System Technology (IWES) were guided by two central questions. Firstly: Which storage method offers sufficient capacity for the varying volumes of renewable energies? And secondly: Which storage facilities can be most easily integrated into the existing infrastructure? The answer was the same in both cases: The storage reservoir of the German natural gas grid with approximately 50 locations and more than 240 individual storage facilities. The grid's storage capacity currently amounts to over 200 terawatt-hours, corresponding to the consumption of several months. By comparison, the electricity grid merely has a minimum buffer of 0.04 terawatt-hours, derived chiefly from pumped-storage hydroelectric plants.

Additional storage capacities

In 2011, Erdgasspeicher Peissen GmbH started building the underground gas storage facility "Katharina". Over the next 15 years, a total of 12 caverns with a working gas volume of approximately 600 million cubic meters will be created in rock salt deposits in Saxony Anhalt. This corresponds to an energy volume of 6.52 billion kilowatt-hours, which would cover the natural gas demand of 300,000 households for a whole year. The caverns will be drilled and leached at depths of 500 to 700 m.

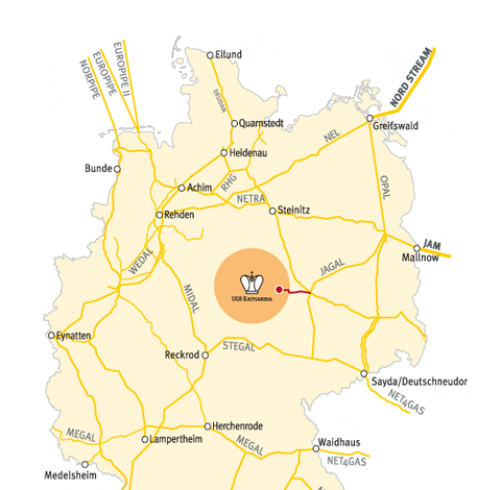

Connection to JAGAL

In addition to the underground caverns, a feed and withdrawal plant and a compressor hall are being built above ground to allow the new storage facility to be connected to the trans-European pipeline grid. In addition, starting in spring this year, a 37 km long connecting pipe is being laid to the JAGAL pipeline which runs east of Katharina.

Increased technical demands on line pipe

Salzgitter Mannesmann Großrohr's long years of experience in meeting the most exacting technical requirements earned it the contract for the supply of the DN 800 spiral-weld pipes needed for the project. Besides steel grade L 525 ME, DWTT: -20 °C, the customer had specified extremely tight tolerances regarding the outside diameter and roundness. For example, the weld reinforcement was not to exceed 0.8 mm. Meeting these stringent specifications was only possible thanks to the excellent coordination between the quality teams of Salzgitter Mannesmann Großrohr and Salzgitter Flachstahl. For several months, they worked out technical ways and means of meeting the high demands. Eventually, when all the procedures had been harmonized with the technical specifications, the hot wide strip was rolled at Salzgitter Flachstahl in four sequences between October and December 2014. The pipes were then manufactured between mid-November 2014 and February 2015 and delivered by truck. Per journey, four to five pipes were transported over 140 km from the Salzgitter pipe mill to two storage yards in the Köthen area. There the pipes were unloaded with a crawler-mounted vacuum lifter, stacked to customer specifications, scanned and linked to GPS coordinates.

Commissioning and start-up in 2017

Construction of the above-ground facilities and the connecting pipe is scheduled for completion by 2017. By then, the number of caverns will have risen to seven, which means the maximum withdrawal potential of about 24 million cubic meters/day will have been reached – another milestone on the way to ensuring supply security for Germany. The last of the planned caverns will then be available in 2024 – maybe for synthetic natural gas from renewable energies, who knows.

Katharina underground gas storage project

The Katharina UGS facility near Bernburg is being built by a Joint Venture of Gazprom Export and Verbundnetz Gas – Erdgasspeicher Peissen GmbH. Its purpose is to bolster reliable gas supplies to Western Europe, including supplies via the Nord Stream pipeline.

UGS Katharina storage capacity

Working gas volume: approx. 605 million cubic meters

Feed capacity: max. 12.0 million cubic meters/day

Withdrawal capacity: max. 24.0 million cubic meters/day

Natural gas storage in Germany

The possible methods include pore storage (in former oil or gas reservoirs or aquifers) and storage in salt caverns. Germany's first underground gas storage facility – the Engelbostel aquifer – was commissioned in 1955. It was abandoned for economic reasons in the late 1990s.