Visit to Salzgitter Mannesmann International USA

Made in Germany, processed in the USA

Thousands of tons of HFI-welded steel tubes and pipes leave Germany each year destined for Houston. Mannesmann Line Pipe and Salzgitter Mannesmann International USA work very closely together. Michael Kosfeld explains how cooperation works locally.

"If we count the predecessor compan- ies in the USA, we’ve been supplying Mannesmann tubes and pipes to the American market since the 1970s," says Michael Kosfeld on the way to the sales office of Salzgitter Mannesmann International USA (SMIH) at St. James Place 1770 in Houston. Coming here regularly since 1990, he has been familiar with the sales office of Salzgitter AG from Day One – which is why he feels just at home here as at his office in Siegen.

On arrival and after a few details relating to his flight and the weather in Germany, he turns his attention to the agenda of the next few days. In addition to meetings in Houston, there are plans for further trips to Tulsa and Denver.

Thanks to his close contacts, Kosfeld knows the trading business in the USA like the back of his hand. "HFI-welded steel pipes are mainly used in two areas in the American market. Firstly as oil and gas line pipe on- and offshore, and secondly as OCTG."

Depending on the order and the customer, the pipes are either stored or immediately processed after their arrival. On completion, the delivery logistics is once again taken over by the SMIH team.

Separation of the sales areas

These two sales areas are clearly separated at SMIH. For line pipe, Kurt Swendson is the responsible seller, and for OCTG, this is Jörg Tilly. They are each supported by further employees of their sales teams. "The back office is absolutely key in trading business here," explains Kosfeld. "Looking solely at our deliveries last year, we’re talking about thousands of ordered items that have to be booked, ordered, produced, tested, customs-cleared, shipped, unloaded and distributed."

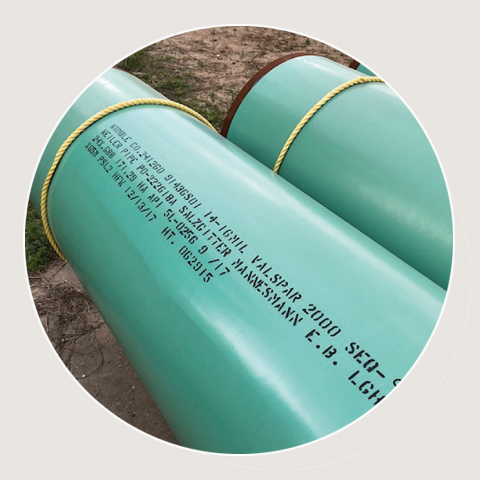

The Salzgitter office does not have any warehouse capacity of its own and operates purely as a trading office. Customers are either direct end users in the energy sector or distributors in the USA. "Our bare tubes are either supplied to threading or coating companies and some of them are stored long- or short-term there." When pipes are then ordered, they are further-processed for the specific order and then sent by the SMIH traffic department to their destination. Kosfeld: "Trading tasks here are shared with the further-processing companies, although distributors and end users are assisted by employees of SMIH and Mannesmann Line Pipe from the order through to delivery."

Meeting on site at Weiler Pipe

To see how this works, we visit Weiler Pipe, a customer and distributor who does business with line pipe: A meeting on site with Landon Weiler and Brandon Mitchell on Houston’s western periphery. "We have a close partnership with Weiler Pipe," says Michael Kosfeld. Visits take place regularly so as to gain as precise a picture as possible of the requirements of the distributor in line pipe business.

Weiler Pipe serves numerous big-name customers in the oil and gas industry, further processors in steel construction, and other pipe distributors. The supply range comprises 8 to 42" (219.1 – 1,066.8 mm) diameters in a huge variety of grades. Like SMIH, Weiler Pipe resorts to different coating service providers and has the pipes stored there until the concrete customer order is received. The pipes are either cut and supplied bare or with single-layer FBE or dual-layer FBE/ARO coatings to customer specifications. Weiler Pipe also handles all the logistics services.

A visit to Weiler Pipe. From left to right (standing): Jess Kindig, Brandon Mitchell; (sitting): Michael Kosfeld, Brooks Weiler, Kurt Swendson

Interview with Brandon Mitchell, Vice President Weiler Pipe

During his visit, Michael Kosfeld asked Weiler Pipe Vice President Brandon Mitchell about customer orientation.

Brandon, how long have you been working with the sales office in Houston?

We have been working with Salzgitter Mannesmann Intenational Houston and Mannesmann Line Pipe for 4 years and have continued to increase our tonnage each year.

Which Mannesmann Line Pipe products sell best?

In recent years we have seen an increase in demand in high yield, larger OD, heavy wall material. Mannesmann Line Pipe is one of the very few mills able to provide this pipe, and our relationship has helped us to meet our customer’s needs in these sizes. Our top selling products are 20" and 24" high yield – X-65 and X-70 material. In 20" it is .500" wall and .594" wall, and 24" is .562" and .625" wall.

What‘s your assessment of cooperation with SMIH and Mannesmann Line Pipe?

We have continued to grow our relationship with Salzgitter because their focus like ours is the customer. They are flexible and work with us to meet deliveries no matter the size of the order and are willing to work through any issues that arise.

Brandon Mitchell, Vice President Weiler Pipe

What‘s Weiler Pipe‘s take on customer orientation?

We have a diversified customer base consisting of major Oil & Gas companies, pipe distributors, and fabrication and construction companies. Our main focus is customer service. We will perform any task required by the customer and work diligently to meet their schedules and deliveries, whether it’s a 2’ piece of pipe or 20 miles.

What are your impressions from your last visit to our mills in Hamm and Siegen?

I visited the mill in Germany last year. I was very impressed with the efficiency and capab-ilities of the mill. The tonnage that is produced with the amount of employees stood out. The mill was very safety conscious and clean. Also, the amount of storage space for completed material waiting for transport was large and well organized.