We make a difference

Getting the curve into the future

The storage of surplus electrical energy generated from renewable sources plays an important role in the context of the energy turnaround. The more electricity we generate from renewable energies, the greater the possibility of a CO2-neutral use of hydrogen and methanized natural gas. An outlook.

Hydrogen for industry

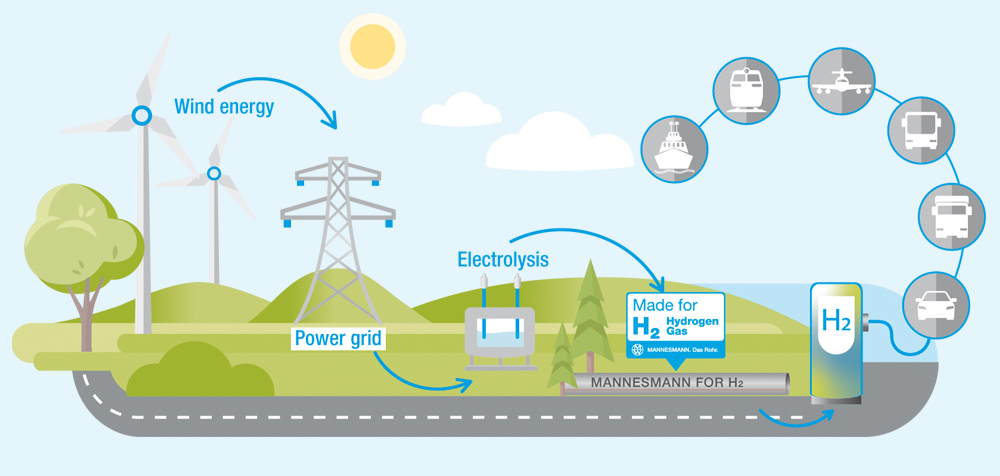

Hydrogen consumption in Germany is enormous. About 20 billion standard cubic meters are produced annually in this country, and worldwide even 500 billion. Usually hydrogen is produced by steam reforming with natural gas. However, this process releases enormous amounts of carbon dioxide. About 10 tons of CO2 are emitted for the production of a single ton of hydrogen. Among the largest industrial users are refineries that need hydrogen to desulfurize petrol and diesel. If renewable energies could be used here for electrolysis, this production would be almost CO2 emission-free, with positive effects on the CO2 balance of conventional fuels. In addition to applications in other chemical sectors, such as drug and fertilizer production, there is a vast potential for the use of green hydrogen or synthetic fuels produced with the aid of green hydrogen in the mobility sector: in inland waterway and maritime transport, in air traffic, as well as in truck and rail traffic.

Power-to-fuel

On behalf of Audi AG, in 2013, ETOGAS GmbH erected a 6 MW pilot plant for the conversion of excess green electricity into renewable natural gas in Werlte, Lower Saxony. Besides hydrogen from regen-erative sources, CO2 from an existing biogas treatment plant in Werlte is also used for methanization. The new plant thus produces renewable fuel, called "e-gas" by Audi. The consumption of the Audi g-tron models‘ vehicle fleet is precisely documented and fed 1:1 into the natural gas grid, so it can actually be termed climate-neutral fuel consumption.

Power-to-gas

Power-to-gas technology converts regeneratively produced electricity into chemical energy in the form of various gases. Water is first split into hydrogen and oxygen by electrolysis and then CO2-methanized. The result is synthetic natural gas. As a matter of interest: Germany has a nationwide infrastructure of over 400,000 km of natural gas pipeline network and over 50 underground natural gas pipe arrays with a current capacity of 23.5 billion standard cubic meters. This could be used for transporting and storing synthetic natural gas. The technological development for the production of green hydrogen using the power-to-gas process is about to establish itself on a large scale. The network operators Tennet, Gasunie and Thyssengas want to promote the storage of renewable energies in gas networks and build a 100 MW plant in northwest Germany. Two locations close to Tennet transformer stations, which mainly bundle and distribute offshore wind power from the North Sea, are possible candidates. The pilot plant is to start in 2022 with a first module, after which a new module will be added every other year until 2028.

Mannesmann pipes for hydrogen transport and storage

Mannesmann Line Pipe can offer its customers suitable products and solutions for the transport and storage of hydrogen. The requirements of EIGA, the European Industrial Gases Association, are generally not a problem. Manuel Simm, Regional Sales Manager at Mannesmann Line Pipe: "For durable resistance to the conditions of hydrogen transport, the inside surface of our pipes is free from weld upsets in accordance with ISO 3183. Potential points of attack in the material itself are limited to a minimum, because the phosphorus and sulphur contents are even lower than specified in the EIGA guideline." And Manuel Simm adds: "The pipe material‘s carbon equivalent has also been reduced, which provides for excellent weldability. The result: low-maintenance operation of the pipe system for a long service life."

The future with hydrogen can come - we are well prepared!Manuel Simm, Regional Sales Manager

H2-pipes – the next step

In order to raise the economic efficiency of hydrogen transport and storage, higher-strength pipe materials and smaller wall thicknesses suggest themselves as possible options. To assess the effects of hydrogen on such higher-strength materials, investigations were carried out together with Salzgitter Mannesmann Forschung GmbH on grade X70 steel (according to API 5L). Round tensile test specimens of the base material and HFI welds were subjected to slow strain-rate tensile tests in an atmosphere of 80 bar hydrogen and 80 bar nitrogen. Manuel Simm explains the results: "Neither in the base material nor in the HFI weld specimen did we observe any relevant influence of the hydrogen on the course of the stress-strain curves, the yield strength or the tensile strength and thus on the strength of the material as a whole. This means that we have also qualified higher grades for use as hydrogen line pipes." His final conclusion: "The future with hydrogen can come - we are well prepared!"