Tembikai offshore gas pipeline in Malaysia

Zap-Lok™, a new dimension in offshore pipe-laying

The Zap-Lok™ offshore method promises considerable savings of time and money over pipe-laying using the conventional welding method. In Malaysia, the method has now been used with a pipe wall thickness of 17.5 mm for the first time worldwide. The quality of HFI-welded steel pipes and the results speak volumes.

The Tembikai oil and gas field is located about 150 km off the east coast of the Malaysian peninsula. Located under 70 m deep waters, it is a so-called marginal oil and gas field and is being developed by the state-owned Malaysian energy company Petronas Carigali. Oil production started in October 2015, and the gas development project was launched in 2018. Vestigo Petroleum, a subsidiary of Petronas Carigali, plans to start gas production in the course of 2020.

Connection via a 60 km long offshore pipeline

To develop the field, it was to be connected via a 60 km pipeline to a drilling platform already installed in 2018/2019. To plan and implement the extensive measures, the Malaysian company Alam Maritim Resources Berhad was awarded the contract, in a consortium agreement with Cortez Subsea, for the engineering, procurement, construction, installation and pre-commissioning of the new pipeline in April 2019.

Activation of the best connections

The Scottish subsea services and technology company Cortez Subsea had already been championing the Zap-Lok™ process in Malaysia for several years. Alam Maritim Resources Berhad had long-standing contacts in the region and was very interested in constructing the pipeline using the economically attractive Zap-Lok™ process. For this project, however, a challenge arose in the calculation of the pipeline dimensions: An outside diameter of 323.9 mm required a wall thickness of 17.5 mm − a size that had never previously been realized using the Zap-Lok™ process. Top priority was therefore initially accorded to a lively and direct exchange of information between customers, end users and the experts at Cortez Subsea, NOV Tuboscope and Mannesmann Line Pipe. Nils Schmidt, the responsible Regional Sales Manager at Mannesmann Line Pipe: "We were able to test and verify the suitability of the Zap-Lok™ connection for offshore use to high safety standards several years ago. After internal consultations we were sure that we would be able to achieve certification for this new dimension as well."

"After internal consultations we were sure that we would be able to achieve certification for this new dimension as well."Nils Schmidt, Regional Sales Manager

Employees monitoring pipeline installation work in the control room on the "Timas 1201"

"All in all, we managed to cut laying costs by about 30 % over the method using conventional welding."Alasdair Cowie, CEO Cortez Subsea Ltd.

Complete faith in our own skills

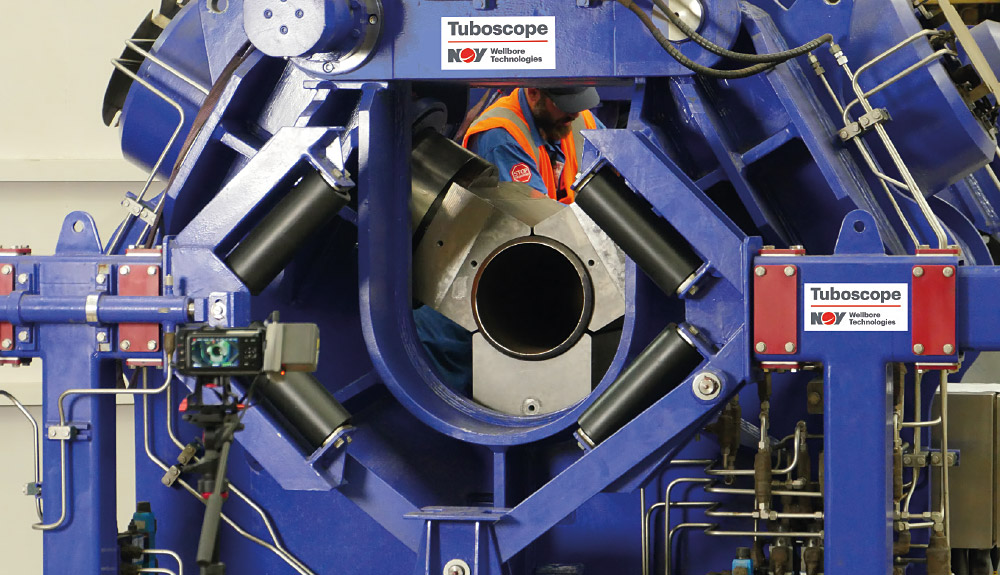

With the envisaged pipe wall thickness of 17.5 mm, this was "new Zap-Lok™ territory" for everyone involved. First of all, the new wall thickness required a brand-new unit, which NOV Tuboscope supplied at short notice from the USA to the Mannesmann Line Pipe site in Hamm. But that was not all: Because of the highly ambitious schedule, it was clear from the outset that both the pipes for testing and qualification on the end user's site and the pipes for the actual customer order had to be produced in a single batch. Nils Schmidt: "We took the full risk. However, we were absolutely certain that the predicted material behavior of the new wall thickness would be confirmed in practice."

Production of the new Zap-Lok™ connections

Within a few days, the pipe connections destined for qualification were first produced on the new unit. For this purpose, the pipes were widened to produce a socket at one end, and a matching groove and chamfer were machined at the other end. "The load results immediately spoke for themselves," says Abdulla Kocatürk of NOV Tuboscope, still very enthusiastic in retrospect. "Now we only had to have the internal results verified."

Extensive quality tests

As soon as possible, the finished test joints were therefore subjected to extensive tests to determine their pressure resistance at the Salzgitter Mannesmann Research Center in Duisburg and at the RWTH in Aachen. A 15-strong delegation of customers and end users eagerly awaited the results. The resultant burst pressures significantly exceeded the requirements of customer specifications, so there were no more technical reservations.

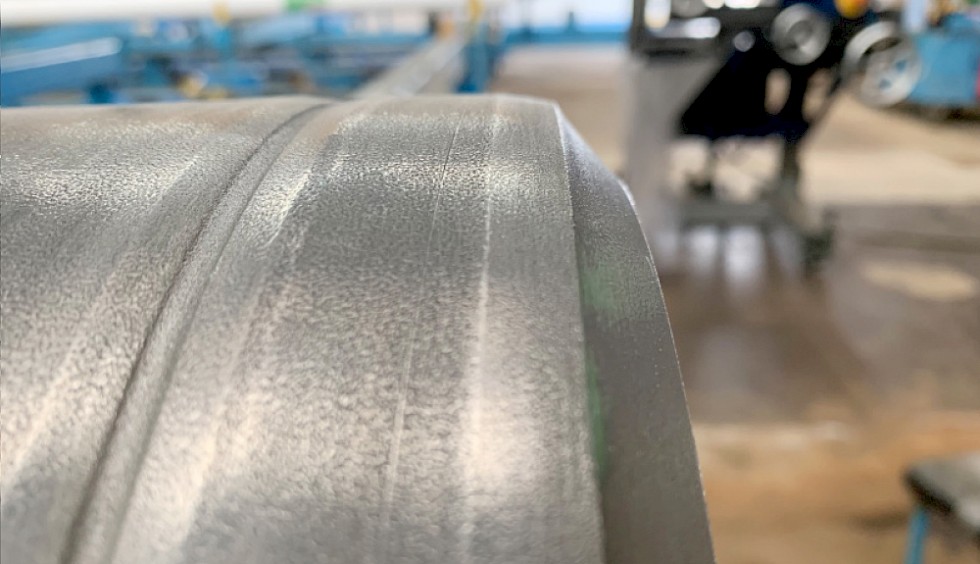

Further processing shared between Siegen and Hamm sites

So as to meet the tight time window for delivery to the Far East, the subsequent application of the HDPP plastic coating in a three-layer process was shared between the Siegen and Hamm sites. Between August and November 2019, the consignment first went by train and truck from Hamm and Siegen to Brake and from there by ship to Malaysia.

Pipe-laying from the Timas 1201

To lay the pipeline, the Timas 1201 was used, an optimally suited multi-purpose heavy-duty pipe-laying vessel. Before the pipe-laying operations could be started, the equipment necessary for producing the weld-free Zap-Lok™ connections was installed on board.

NOV Tuboscope supplied the brand-new unit for the production of Zap-Lok™ joints from the USA to Mannesmann Line Pipe's Hamm site at short notice.

High-tech assignment even underwater

The use of state-of-the-art underwater cameras meant that no divers were needed for installation. The application enabled high-precision measurements underwater with an accuracy of +/- 1 mm. This ensured maximum precision and speed for pipeline crossings, connections and surveying work. The data generated in this way were additionally used to create a 3D visualisation of the finished pipeline. Among other things, this will serve as a basis for future inspections.

Huge cost savings

The installation of the pipeline with a total of 5,100 Zap-Lok connections was completed within 20 days at an average laying rate of 4.7 km per 24 hours. Alasdair Cowie from Cortez Subsea sums it up: "The mutual trust of all those involved made the project a complete success. All in all, we managed to cut laying costs by about 30% over the method using conventional welding."

The Zap-Lok™ laying process

The pipeline was laid using the patented Zap-Lok™ connection developed and patented by NOV-Tuboscope. The system enables a weld-free, semi-autonomous laying process and offers several advantages:

Tested safety

Zap-Lok™ technology is proven and safe with over 7,000 km of pipelines laid and more than 70,000 flawless connections. The mechanical alternative results in higher occupational safety and requires neither welds nor X-ray tests.

Speed

With the weld-free Zap-Lok™ method, approximately 3.5 to 5 km of pipeline can be laid in 24 hours. This is about three and a half times faster than the conventional method.

Lower cost

The method not only reduces the number of ship charters, but also lowers manpower costs enormously. With Zap-Lok™, cost savings of up to 40 % are possible.

The method is particularly suitable for shallow waters and for water depths of up to 90 meters. The pipe diameters extend to 406.4 mm and wall thicknesses currently up to 17.5 mm. HFI-welded pipes from Mannesmann Line Pipe can be provided with various coatings and linings to suit customer requirements and specifications. Customized solutions are standard in this product segment as well.