Change and transformation

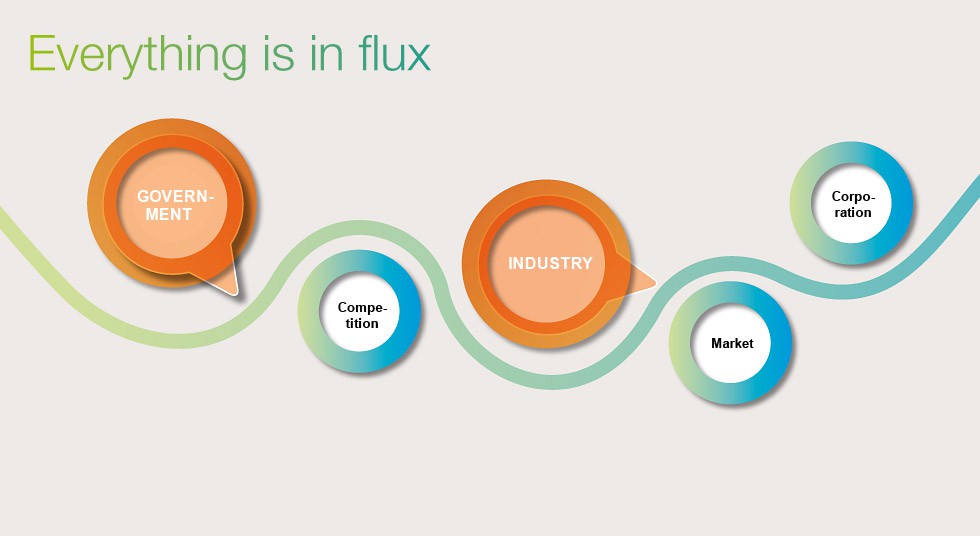

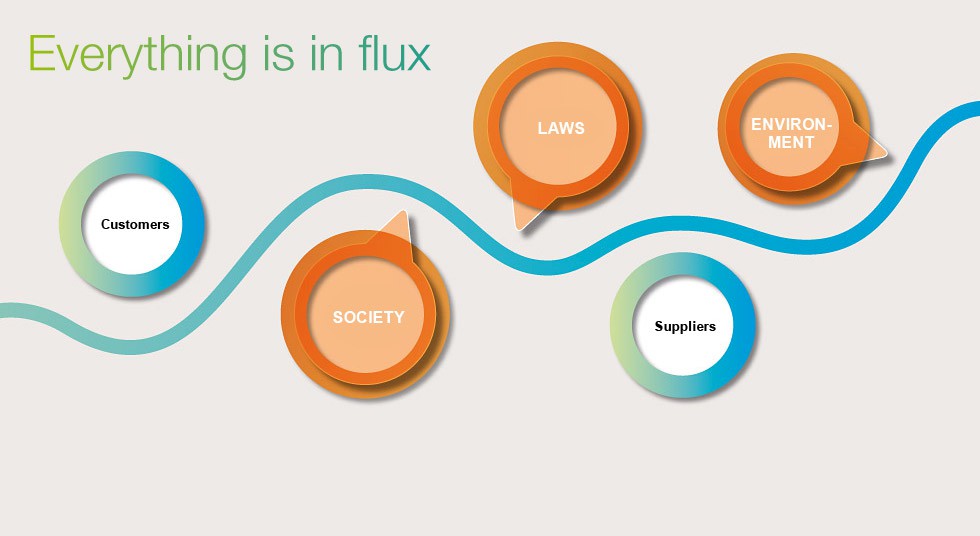

Everything is in flux

“You cannot step into the same river twice,” said the Greek philosopher Heraclitus. 2,500 years later, not only is everything still in flux, but the critical parameters have become more incalculable than ever. Salzgitter Mannesmann Line Pipe has responded to this and is actively shaping change – for itself and its customers.

Globalization, etc.

Globalization, digitization, Industry 4.0, the energy turnaround, cheap imports, the shortage of skilled manpower, oil price trends, and resource management: these are all themes illustrating that the issues that industry has to deal with today are not only growing in number, but are also becoming ever more complex. How are stock market prices reacting, what does this mean for exchange rate parities, and what are the repercussions on economic growth and the oil price? What will be the effects for customers, suppliers, competitors and the market situation, nationally and internationally? The refugee crisis, demographic change, emerging protectionism, and Brexit all compound the volatility of the scenario.

Only one thing seems to be certain: reliable forecasts in the short, medium and long term are becoming more and more difficult, if not impossible.

More turbulence than ever

The once slow-moving river has now gathered pace, and rapids, changing directions of flow, and unforeseeable obstacles are becoming increasingly common. Under these conditions, planning for the long term seems to be a more difficult undertaking than ever. So as a long-standing manufacturer of HFI-welded steel tube and pipe that is benefiting from globalized markets and is also dependent on them, how should we act?

A watchful eye on the market, and a focus on the customer

In concrete terms, Salzgitter Mannesmann Line Pipe is experiencing the externally influenced changes like this: under the effect of political uncertainties, rewarding markets are collapsing practically overnight. Contacts with regular customers are severed by protectionism. The fluctuating oil price and currency risks are showing their effects: Projects that appeared to be on the safe side are becoming uncertain or are canceled altogether.

“Responding closely to customer needs, analyzing existing markets, and identifying new market potential still have top priority for us when it comes to strategic corporate development,” says Konrad Thannbichler, Sales Director at Salzgitter Mannesmann Line Pipe. “Staying with the ‘river’ imagery, we can imagine a speed boat that races ahead of the mothership and keenly monitors the banks, the course of the river and rapids, and reports straight back to the bridge of the ship.”

The be-all and end-all is still close customer relations. Salzgitter Mannesmann Line Pipe has consistently extended its range of high-quality HFI-welded steel pipe and tubes and MSH sections in the last few years.

Thannbichler: “Our customer advisers and sales staff support our customers in their projects from start to finish. Advice covers everything from the choice of laying method and technical specifications through to further treatment.”

The complete logistics process, including customs clearance, haulage and shipping company paperwork, is all handled single-source at Salzgitter Mannesmann Line Pipe. For Thannbichler, being close to the customer then also entails local service on the pipe-laying site. “From how customers and processing firms use and evaluate our products, we can draw important conclusions in terms of changes in our product and service portfolio,” says the 48-year-old.

Always on the move and up among the leaders

Change is by no means new to SMLP. Thanks to its closeness to and cooperation with customers and partners, the product and service portfolio for our HFI-welding steel pipes and tubes and MSH sections has been steadily expanding over the last few years.

Our consistent focus on the needs and requirements of our customers is a key factor in the ongoing development of our products and services. Change for us is thus an everyday activity and can be observed on a multitude of levels.

Innovative technologies

With research and development, we are constantly advancing innovative technologies for the production, further processing and application of our products.

-

Laser welding

In cooperation with the SLV Halle welding training and testing center, we are working on a project for laser-assisted welding. The objective is to combine the welding and testing of pipe joints in a single operating step.

-

Cathodic corrosion protection

Cathodic corrosion protection allows the monitoring and assessment of both new and in-situ pipelines. Salzgitter Mannesmann Line Pipe accompanies the development work and participates in the compilation of corresponding standards.

-

Flowlines

Secondary oil recovery places extreme requirements on the steel pipes used in oil gathering systems. Salzgitter Mannesmann Line Pipe has developed a particularly economical system solution for this application.

-

ZAP-Lok® connection

The patented connection system does without welding by exploiting metal-to-metal friction. The technique is suitable for all common pipeline applications (sour/non-sour gas, oil, water) as well as for offshore and high-pressure pipelines in diameters of 60.3 to 323.9 mm.

-

PMT® lite – app for pipeline management

Our app for digital pipeline management – a world-first and now with a proven track record – opens up new scope for on-site work at the pipeline.

Alternative laying methods

When it comes to cost-cutting and environmentally safe laying techniques for pipelines, we assist our customers from project planning through to laying on site. We have a wealth of expertise in the following areas:

- Trenchless pipe-laying

- Plowing method

Coatings and linings

We have a broad range of options for coatings and linings. New and further developments are available in the following areas:

- Polyethylene

- Multi-layer PP/PA coatings

- Maintenance-free corrosion protection for foundation structures in offshore wind parks

- Heavy concrete (inside and outside)

Higher-grade materials

Thanks to the high quality standards of our premium-grade materials, our products are continuously being improved.

-

Structural tube and MSH sections

The new MHQ product generation was unveiled at bauma 2016. The high-strength and specially heat-treated tubes and sections combine higher loading capacity with reduced weight.

-

Grade X8Ni9 replaces stainless steel pipes for LNG transport

X8Ni9 pipes from Salzgitter Mannesmann Line Pipe have been used by FW-FERNWÄRME-TECHNIK GmbH as the inside pipe in the FW-KAMMER-PIPE since 2016.

-

Green Tubes J55 UPG

These meet the requirements of API-5-CT grade J55 and can be used as grade J55 oilfield pipe. In addition, they can also be subsequently heat-treated to meet the more exacting requirements of N80 Q, L80 and P110.

Certificates

-

Environmental Product Declaration

Salzgitter Mannesmann Line Pipe is the first company in Germany to have its Environmental Product Declaration (EPD) verified by Institut Bauen und Umwelt e.V. for the production of steel line pipe. EPDs permit the comparison of various products from the environmental point of view, e.g. in terms of the life-cycle analysis, and play an important part in certification systems for sustainable construction.

-

Energy management

Our existing quality management to DIN EN ISO 9001 was extended in 2002 to include environmental management conforming to DIN EN ISO 14001. The energy management system to DIN EN ISO 50001 followed in 2012.

Partners, suppliers, corporation

We always strive for long-term partnerships and customer relations. This makes us a company to depend on.

-

Salzgitter Group

Within the Group, we are excellently connected, from steel production and rolling expertise through to further processing.

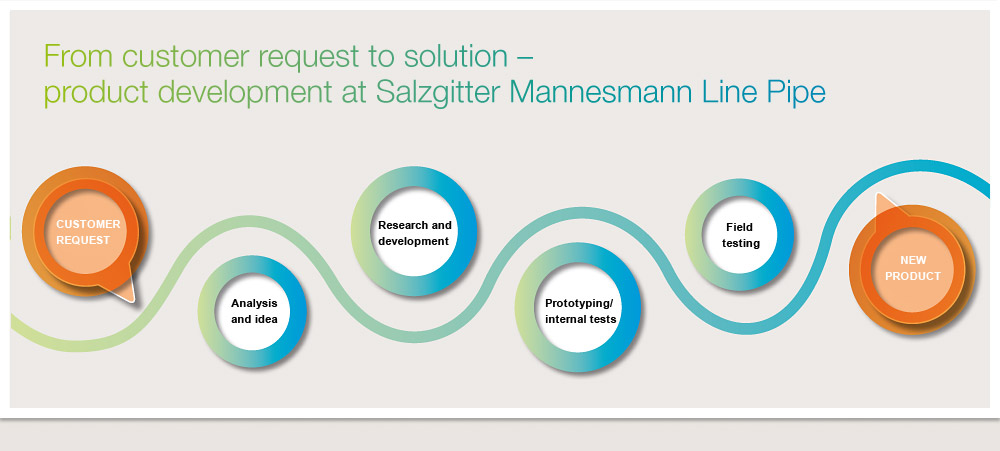

Innovation

Innovation often starts with customer needs. Working from their requests, ideas are generated and then discussed in the research and development department. After the development of prototypes, internal tests are carried out followed by field testing.