Beatrice Offshore Windfarm Limited

Electricity from offshore wind power for up to 450,000 households

The ever-increasing complexity of projects calls for utmost flexibility of the companies involved in their realization. This also goes for the Beatrice project for the construction of an offshore wind farm off the northeastern coast of Scotland, for which Salzgitter Mannesmann Line Pipe supplied tubes to five contractors in Germany, Poland, Denmark, the Netherlands, Belgium and Scotland.

The wind farm Beatrice, situated in the Moray Firth bay, is scheduled for completion by 2019. 13.5 kilometers off the coast, a total of 84 offshore wind turbines will be installed, totaling a generating capacity of 588 MW of electric power from renewable energies. This is enough to power up to 450,000 households.

International operator consortium

The 3.15 billion euro (2.6 billion GBP) project is being handled by Beatrice Offshore Windfarm Limited, an operator consortium consisting of the Scottish energy supplier SSE, Copenhagen Infrastructure Partners, and Red Rock Power Limited, a subsidiary of the Chinese company SDIC Power Holdings Co. The new-generation 7-MW wind turbines to be installed in the wind farm feature rotor blades with a diameter of 154 m. On completion, the wind farm will be operated from its O&M base in Wick.

Erection and connection

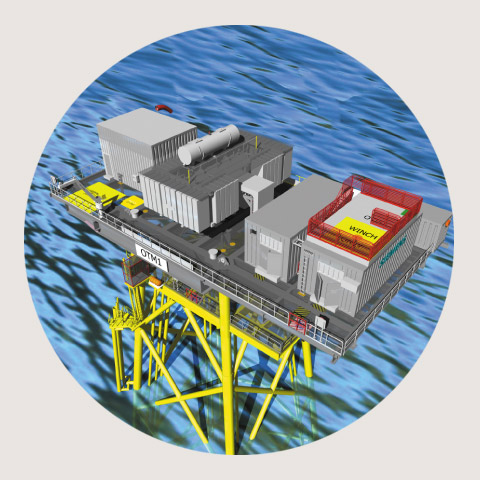

The 84 wind turbines of the powerful 7-MW generation will be supplied by Siemens Wind Power. The Energy Management Division of Siemens and the Nexans company will provide for their connection to the grid. Nexans will supply and install the about 260 km cabling required for this purpose. Seaway Heavy Lifting, a Subsea 7 company, will be responsible for the manufacture and installation of the foundation structures and for the installation of the two offshore transformer modules (OTMs) needed for grid connection, which will also be supplied by Siemens.

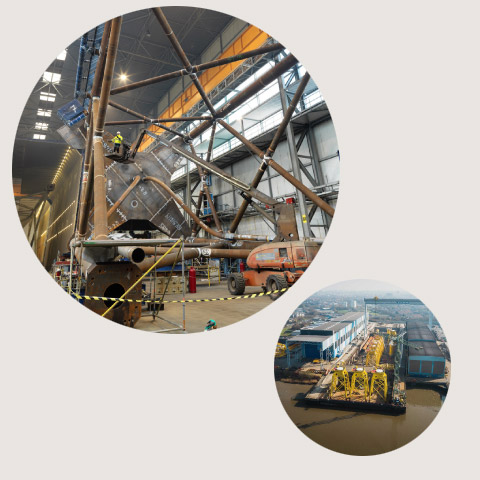

Smulders Projects was awarded an order for the manufacture of 28 foundation structures. The HFI-welded tubes supplied were used as J-tubes. Photos © Smulders

The 75 m long rotor blades are manufactured in the British town of Hull. Photos: © Siemens AG

Installation of the turbine foundations

Seaway Heavy Lifting split the contract for the manufacture of the 84 jacket foundation structures. Thirty of them are made at the Danish Lindoe Industrial Park by Bladt Industries, 28 were awarded to Smulders Projects, and the remaining 26 will be manufactured by BiFab at its Burntisland, Methyl and Arnish facilities. The foundations are up to 71 m high and weigh in at up to 830 tons each. They will be set up on an area of 131 km² with water depths of up to 58 m.

Make three plus two from one

What looked like a straightforward parts list to Salzgitter Mannesmann Line Pipe at the time of the project enquiry turned out to be a much more challenging task than previously thought. Given the split orders for the foundation structures, one enquiry had turned into three separate orders from Edgen Murray (UK), Helens Rör (Denmark) and Vallourec in Düsseldorf. Furthermore, additional quantities had been ordered for the project by the stockists NTS (UK) and Salzgitter Mannesmann Stahlhandel Sp. z o.o. (Poland) via stock orders and framework agreements. Accordingly complex were the planning and coordination of the orders, which were internally split into lots, from starting material orders through to the production of the steel tubes at the Hamm and Siegen locations.

Deliveries to nine locations in six countries

Things got even more complicated when it came to delivering the finished tubes. The delivery had to be split once again, with further destinations having to be planned and scheduled. In all, deliveries had to be made to nine corporate locations in six European countries. "This project is a typical example of the increasing division of work in many industries," says Guido Ludwig, who was responsible at Salzgitter Mannesmann Line Pipe for the demanding project. "One company alone can no longer offer the complete package at an affordable price." In all, more than 1,000 tubes were supplied, with diameters ranging from 457 to 610 mm and wall thicknesses of 12.5 to 25 mm. The lion's share was used as cable sheathing tubes on the jacket structures. "It's quite unusual, of course, to have to make deliveries to five dealers and customers at nine locations in six countries – all for the same project." Thanks to the experienced sales and logistics staff it was even possible to accommodate short-term changes and customer requirements.

Novel grid connection

For the first time, connection to the mainland grid will be effected via a modular concept with two offshore transformer modules (OTMs), which will collect the generated electricity and transform it from 33 kV to 220 kV for transmission to the shore via two 69 km cables. The modules are one third smaller and lighter than a conventional alternating-current transformer station and expected to reduce connection costs by about 40 %. In a further transformer station on the mainland, the electricity will be transformed to 400 kV and then distributed further inland.

Offshore power for less than 8 euro cents/kWh

With the completion of the new wind turbine blade manufacturing plant in the British town of Hull in 2016, and nacelle production in Cuxhaven, Germany, beginning in mid-2017, Siemens is expecting an efficiency boost in wind energy generation. The enterprise announced that it will bring the cost of power generation from offshore wind down to less than 10 euro cent per kilowatt-hour by 2020, and to less than 8 euro cent by 2025. Offshore wind farms will thus generate power that is both ecological and economical. Beatrice will contribute towards this as early as 2019.

Visualization of the new offshore transformer module. Picture: © Siemens AG