Construction of new Halls C5 and C6 at Messe München

"This wouldn’t have been technically possible 15 years ago."

Back in the 1990s, exhibition halls with highly ambitious architecture were erected at Munich’s trade show center. With the construction of the new Halls C5 and C6 and the Conference Center Nord, the covered exhibition space is set to grow to 200,000 m² by 2018. Involved for the first time are HFI-welded steel tubes from Hamm and Siegen.

"Messe München is in great shape economically and strong," explained trade show company CEO Klaus Dittrich in his annual review on January 12, 2017. Sales passed the EUR 400 million mark for the first time in 2016. Thanks to reserves and foreign business, which now accounts for 22 percent of total sales, the exhibition company can continue to invest on a large scale – in two new exhibition halls, for example, which are due for completion in 2018.

The difference in the details

This is also the first time that Salzgitter Mannesmann Line Pipe is supplying components for the sophisticated roof structure of the new halls, which are virtually identical to those dating back to 1996 to 1998. The difference can be found, however, in the details – and in by no means unimportant ones. While seamless tubes were exclusively used for the original elaborate steel structure, HFI-welded tubes from Hamm and Siegen are now being utilized as well.

Guido Ludwig, Area Sales Manager Structural Tubes at Salzgitter Mannesmann Line Pipe, explains: "We are delighted that Messe München has chosen our tubes. Longitudinally welded tubes as produced by Salzgitter Mannesmann Line Pipe have now become broadly established as a technical and above all economic alternative to seamless tubes, for example," Ludwig adds: "This wouldn’t have been technically possible 15 years ago."

Continuous development of higher grades

The higher-strength grades that Salzgitter Mannesmann Line Pipe is now capable of producing in this area are decisive. In addition, the company can draw on its wealth of experience from numerous challenging steel construction projects in the last few years. "Here we are supported by starting material suppliers and research facilities within the group," adds Manfred Veit of Quality, who has also served steel construction projects like the New Safe Confinement in Chernobyl and the new soccer arena in Danzig for the Euro 2012 tournament.

The finished hall ensemble is due to look like this as of 2018: Simulation of the new Halls C5 and C6 and the Conference Center Nord in the foreground.

Groundbreaking on June 28, 2016 (from left to right): Klaus Dittrich, Messe München; Ilse Aigner, Bavarian Minister of Economics and Media, Energy and Technology; Dieter Reiter, Lord Mayor of Munich; Peter Driessen, General Manager of the Chamber of Industry and Trade of Munich and Upper Bavaria; Franz Xaver Peteranderl, Vice President of the Chamber of Crafts of Munich and Upper Bavaria

"Putting together the best-possible package for the customer."

Higher strength, lower weight, lower price

Numerous design offices, engineers and steel construction companies appreciate HFI-welded steel tubes as the more economic and also technically superior solution. Longitudinally welded tubes can be produced with tighter tolerances, more flexible lengths and a visually better-quality surface. In some cases, it's the fact that they are also lighter than their seamless equivalents that makes spectacular structures possible.

Two suppliers, one package

For the extension of the new Messe München, Salzgitter Mannesmann Line Pipe joined forces with Vallourec in bidding for the project. The two companies are linked by many years of cooperation. In terms of this project in particular, it soon became obvious that certain dimensions could only be produced seamless. On the other hand, the much-demanded diameters of 168.3 / 244.5 / 273.0 und 323.9 mm with wall thicknesses of between 5 mm and 20 mm could be produced by Salzgitter Mannesmann Line Pipe at a much more competitive price in HFI-welded steel tubes. Ludwig: "What would make better sense than for us to team up in meeting the technical specifications and putting together the best-possible package for the customer?"

High quality and flexibility are decisive

This package made such an impression on the customer Stahlbau Wegscheid that it ordered a total of 424 metric tons of steel tubes from Salzgitter Mannesmann Line Pipe through Vallourec in January 2016. In addition to the competitive pricing and high product quality, the customer also attached importance to flexibility in production and delivery. For instance, it was always possible to change the exact lengths until shortly before production.

Spectacular millimeter-precision maneuver: A total of 13 roof trusses per hall were lowered by crane onto the side walls of future Halls C5 and C6. The steel structures weigh up to 92 tons.

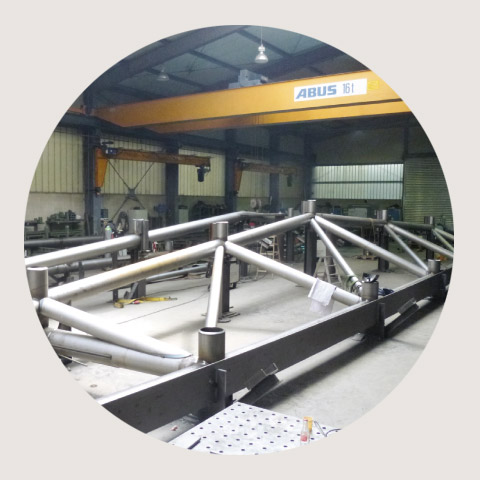

The required components were welded and painted at Stahlbau Wegscheid.

867 tubes for 20,000 m² of exhibition space

From May to August 2016, the steel tubes of grades S235JRH and S355JGH were produced at the plants in Hamm and Siegen and then supplied for further processing to the Wegscheid production location in the immediate proximity of the German-Czech border. It was here that the precisely cut-to-length tubes were welded into components of the roof frame and painted before being shipped to the outdoor grounds opposite the construction site in Munich at the beginning of 2017. It takes two such components to form a 60-meter long roof truss, 13 of which form the self-supporting roof structure of each hall. Topping out is scheduled for June 20, 2017.

Supplier and exhibitor in one

Messe München is of interest to Salzgitter Mannesmann Line Pipe not only as a customer, but also as an exhibition venue. The pipe manufacturer regularly participates with its own stand in IFAT, the world’s leading trade show for environmental technologies. In May 2016, Salzgitter Mannesmann Line Pipe was also co-exhibitor for the first time at "bauma", the trade show for construction machinery with the world’s largest exhibition area (see information box below).

New MHQ product generation

It was also in this context that Salzgitter Mannesmann Line Pipe premiered its new "MHQ" product generation. Under Guido Ludwig’s supervision, suitable trade show samples were presented and new possible applications discussed with the interested professional audience. In the form of high-strength and specially tempered HFI-welded steel tubes and MSH sections, the products of the MHQ generation can withstand higher loads while achieving significant weight savings. "This is where we come full circle. For these tubes are bound to be used in the coming generation of construction machines and in future halls, sports stadiums, and other prestigious architecture," says Guido Ludwig casting an optimistic glance into the future.

Messe München – from local to global

Messe München – from local to global

With over 50 trade fairs at its Munich location and abroad, Messe München ranks among the world's leading trade fair organizers.

In 2016, events at the International Congress Center (ICM) and the Munich Veranstaltungscenter (MOC/Event Center) attracted close to 37,000 exhibitors and 2.4 million visitors.

Messe München is present around the globe, with a network of associated companies in Europe, Asia and Africa and over 60 foreign representations for over 100 countries. Internationally, trade fairs are organized in China, India, Brazil, Russia, Turkey, South Africa, Nigeria, Vietnam and Iran.

After moving from the center of Munich to the former airport site in Riem in 1998, the trade fair company has one of the world's most modern and sustainable trade fair centers at its disposal and has been certified as an "Energy-efficient Enterprise" by TÜV Süd.

As of 2018, the gross exhibition area, including the two new Halls C5 and C6, will cover some 200,000 m².

The outdoor area of 425,000 m² is the largest of all trade fair companies in Germany.

In all, 213 events and additional guest events were organized under the umbrella of Messe München in 2016. Of these, 16 took place in Munich and 28 abroad. In addition, Messe München hosted 169 congresses and events. The event with the highest visitor turnout – and also the world's largest trade fair in terms of exhibition space – is the triennial construction equipment trade fair "bauma", which was attended by some 580,000 visitors in 2016.